Stainless Snap Fasteners: Where Durability Meets Aesthetics

Stainless steel snaps are an important accessory preferred in many different sectors where durability and aesthetic appearance are sought together. These accessories, especially have a wide range of uses in sectors such as textiles, furniture, leather craftsmanship, and even automotive modifications. Among the reasons for choosing stainless steel snaps are the inherent characteristics of the material, especially its superior resistance to rust. This article will comprehensively cover the features, usage areas, market situation, and future forecasts of stainless steel snaps. In addition, comparisons will be made with other types of snaps in terms of cost, durability, and aesthetics.

The wide usage of stainless steel snaps makes them an indispensable element in many sectors, beyond just being an accessory. The aim of this article is to examine in detail which features of stainless steel snaps have spread their use so broadly and to determine the advantages they offer. Based on this information, the future market potentials of stainless steel snaps will also be assessed.

Following this introduction, we will take a more in-depth look at the features of stainless steel snaps. We will continue with options for size and color.

Features of Stainless Steel Snaps Fasteners

Stainless steel, as a material used for snaps, has many advantages. This section will detail the features of stainless steel snaps and compare them with other types of snaps.

Material Properties of Stainless Steel Snap Fasteners

Stainless steel snap buttons is an alloy that offers excellent resistance to corrosion. This feature is due to the fact that it does not contain elements such as chromium and nickel. There is a protective layer on the steel surface against rust and other environmental factors from the material itself. This layer provides protection against factors such as moisture and salt that the snaps are exposed to during long-term use.

Price and Durability Comparison

Stainless snaps are generally more affordable than pinch snaps because the production processes are more complex and the materials used are of different quality. However, compared to snaps made of sheet iron, the price difference is much more reasonable. While sheet iron snaps are durable, stainless steel snaps offer superior protection against rust and corrosion. This feature makes it especially ideal for outdoor applications and humid environments.

Functionality and Cost-Effectiveness

Stainless steel snaps offer similar functionality to other popular materials like brass snaps but are generally more cost-effective. This cost efficiency is particularly favored in large-scale productions or projects where cost is a critical factor. Stainless steel also has high tensile and fatigue strength, making it suitable for applications where physical stress is high.

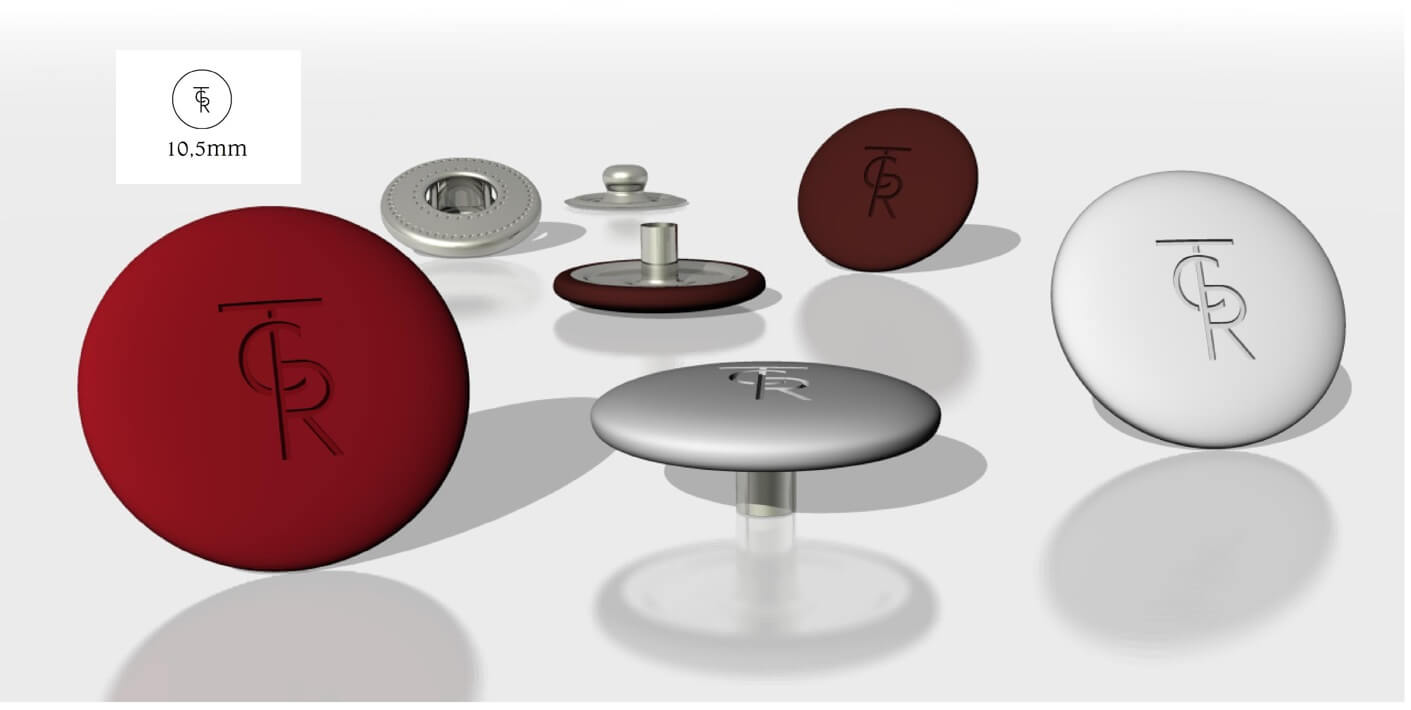

Size and Color Options for Snaps

The versatility of stainless steel snaps is supported by the variety of size and color options they offer. This section will detail these options and how they can be selected according to application areas.

Size Chart

Stainless steel snaps are available in various sizes, and choosing the ideal size for each application can significantly affect the product's functionality and aesthetics. Here are the most commonly used stainless steel snap sizes:

- Mini Snaps: Typically 5 mm in diameter, used for thin fabrics or products requiring delicate craftsmanship.

- Standard Snaps: 10 mm in diameter, the most commonly used size for general clothing and accessories.

- Large Snaps: 15 mm or larger diameters, ideal for heavy-duty applications, such as in outerwear or furniture upholstery.

- These sizes should be selected based on the area of use and the characteristics of the material. Larger snaps provide more strength and holding power, while smaller snaps are less noticeable and offer a more aesthetic appearance.

Color Options fo Stainless Steel Snap Buttons

Stainless steel snaps are usually in their natural steel color but can also be offered in various colors thanks to modern production techniques. These colors include black, gold, silver, and bronze. Colored snaps are particularly popular in fashion and accessory design because they can aesthetically match various fabrics and materials.

Color selection is usually made based on the area where the product will be used and aesthetic requirements. For example, matte black snaps are often chosen for outerwear, while brighter and more vibrant colors may be suitable for children's clothing or lightweight summer garments.

Usage Areas of Stainless Steel Snaps Fasteners

Stainless steel snaps, thanks to their versatility and superior properties, are successfully used in many different sectors. This section will discuss the various uses of these snaps and the benefits they offer in these areas.

Use in the Textile Sector

Stainless steel snaps have a broad range of uses in the textile sector, from clothing items to accessories. Here are some examples:

- Coats and Outerwear: Large snaps, capable of holding heavy fabrics, are frequently used in outerwear products. Stainless steel is ideal for these types of products exposed to weather conditions because it is resistant to rust and corrosion problems.

- Jeans and Workwear: Due to their high strength, they provide durability in frequently used and wear-prone garments like jeans.

- Dresses and Shirts: Small and aesthetic snaps are suitable for light fabrics and offer an elegant closure solution for shirts or dresses.

- Baby Products: Safety and ease of use are very important in baby garments. Stainless steel snaps are often chosen for baby products do not contain harmful substances.

Use in the Furniture Sector

Stainless steel snaps are also effectively used in furniture manufacturing. They are particularly chosen for assembling upholstery materials:

Upholsteries: Used to secure leather or fabric coverings on sofas and armchairs, stainless steel snaps provide a durable and long-lasting solution in such applications.

Use in the Automotive Modification Sector

Stainless steel snaps are utilized in vehicle interiors, seats, and other modifications. They are ideal for interior materials exposed to humidity and temperature changes.

Use in the Leather Sector

Stainless steel snaps are indispensable in the production of bags, belts, and other leather goods. They offer an aesthetically pleasing look that complements leather and do not damage the material’s natural structure.

Use in the Tent and Bag Sector

Stainless steel snaps used in outdoor products and bags offer superior protection against water and external factors. They also provide excellent durability in applications that are under constant tension, such as tents.

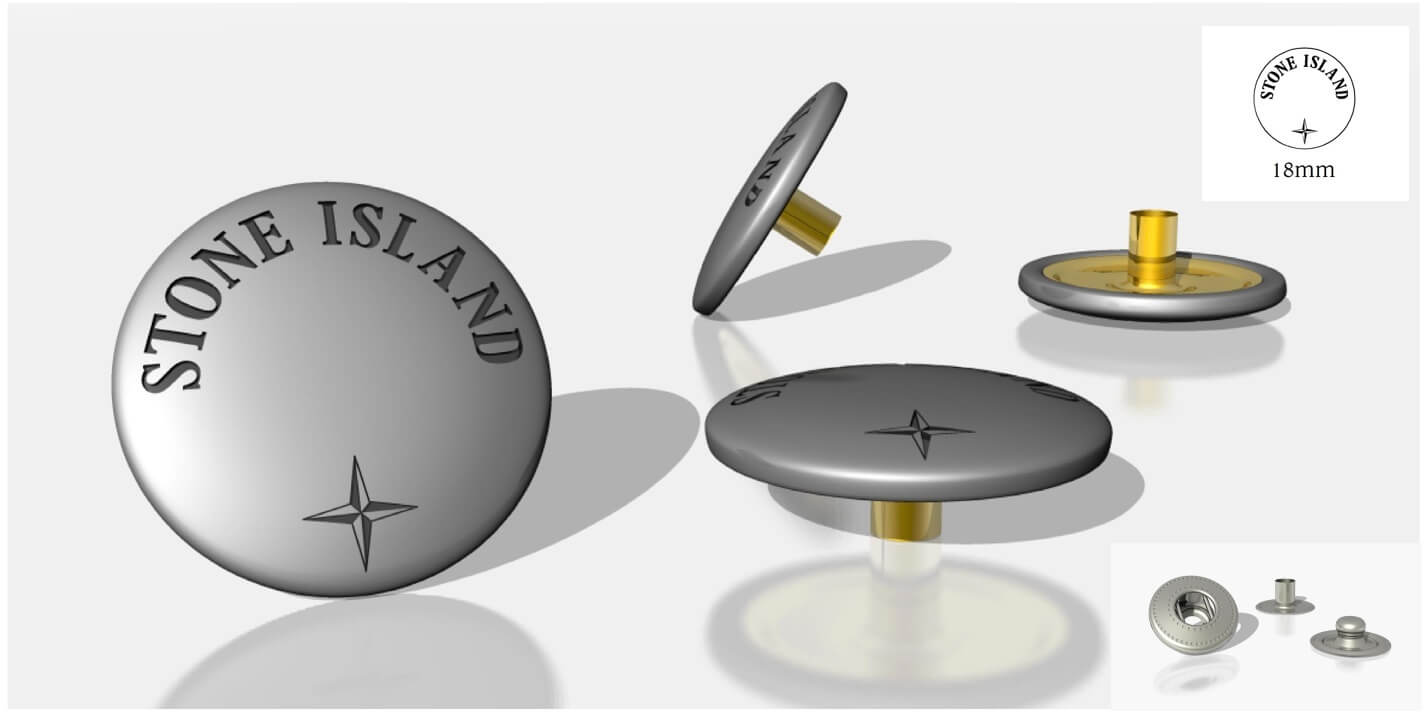

Technical Specifications and Installation Processes

Stainless steel snaps are chosen for their high technical specifications and easy installation processes. This section will thoroughly discuss the technical properties of stainless steel snaps and the methods of installation.

Technical Specifications

Stainless steel snaps are particularly noted for their high tensile strength and fatigue resistance. Below are some of the important technical properties of these snaps:

Corrosion Resistance: Stainless steel creates a protective passive layer by reacting with oxygen, thanks to the chromium content, which prevents the material from corroding. Mechanical Strength: With their high-strength structure, stainless steel snaps can maintain their form even under extreme load, tension, and pressure. Thermal Resistance: Stainless steel snaps are known for their stability across a wide temperature range, making them suitable for use in both hot and cold environments. Aesthetic and Design Flexibility: Modern manufacturing techniques allow stainless steel snaps to be produced in various colors and designs, making them a preferred material aesthetically as well.

Installation Processes

The installation of stainless steel snaps can vary depending on the material and area of application. Generally, the installation process involves the following steps:

Surface Preparation: The surface where the snaps will be mounted must be clean and flat. Dirt, oil, or other foreign substances on the surface can weaken the snaps' grip. Drilling Holes: Holes are drilled at appropriate sizes for the snaps to be mounted. The hole size should be adjusted according to the snap's size and the surface. Placing the Snaps: Snaps are placed into the holes. During this process, special pliers or a mounting tool may be used to ensure the snaps are properly seated. Testing: After the installation is complete, it is tested to ensure the snaps are correctly mounted and provide the necessary holding strength.

Market Analysis and Future Projections

The market status and future potential of stainless steel snaps are directly related to the product's technical properties and broad usage areas. This section will conduct a current market analysis and predict the future path of stainless steel snaps.

Market Status

Stainless steel snaps are in a strong position in many industrial and consumer markets, particularly where durability and aesthetic needs are considered. These products, due to their high-quality materials and promises of long-lasting use, are preferred especially in luxury and semi-luxury product categories. In sectors like furniture, automotive, leather goods, and textiles, the use of stainless steel snaps is increasingly growing.

Market Trends

Market trends evolve depending on changes in consumer preferences and technological innovations. Sustainability and eco-friendly production methods are among the main factors shaping the market. Stainless steel snaps, being made from recyclable materials and offering long-lasting durability, fit well with green production trends. Additionally, the increasing demand for modular and customizable product designs further solidifies their presence in the market.

Future Projections

The future of stainless steel snaps seems to be shaped by advancements in innovative manufacturing techniques and materials science. Particularly, progress in nanotechnology and surface treatment technologies could further enhance the performance and aesthetic features of these products. As the market expands, it is expected that stainless steel snaps will find more diverse and customized applications.

Moreover, optimizations in global supply chains and reductions in production costs could make stainless steel snaps more accessible to a broader consumer base. This would increase the market size and the accessibility of the product.

This article has provided a comprehensive review of stainless steel snaps, explaining why they are so valuable and preferred. Understanding their features, application areas, and market potentials provides valuable insights for individuals and companies in related industries

-no5-k0010%20(3)-590x590.jpg)

-230x230.jpeg)

-230x230.jpg)

-230x230.jpeg)

-230x230.jpg)

Leave a Comment